For vacuum injection process

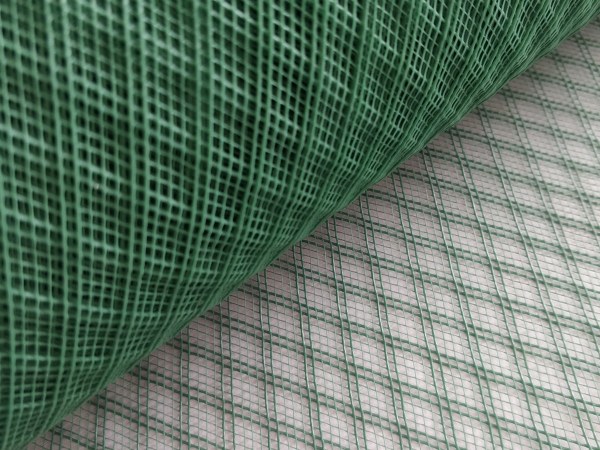

Resin infusion mesh, also known as resin flow mesh, is generally made of HDPE and is a high permeability flow media used for composite vacuum injection process. It works well with polyester, vinyl ester and epoxy resins. It drives the resin to flow to the designated position of the mould and accelerates the flow rate. Multilayer infusion mesh can be overlapped when large volumes of resin flow are required.

Like most vacuum accessories, resin infusion mesh cannot be recycled, so it is disposable consumable. It applies to products of any size, for example, car hoods, car panels, ship building and wind blades, etc.

For vacuum injection process